Introduction

In today’s fast-paced world of modern manufacturing, the choice of materials plays a crucial role in ensuring the quality, durability, and cost-effectiveness of products. Among the various materials available, Cold Rolled (CR) Sheets and Mild Steel (MS) have emerged as staples in the industry. In this blog, we will explore the numerous advantages of CR Sheets and Mild Steel, shedding light on why they are preferred choices for modern manufacturing processes.

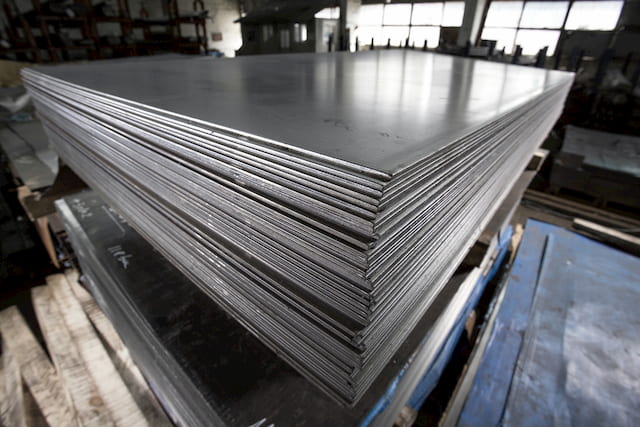

CR Sheets: A Brief Overview

Cold Rolled (CR) Sheets are steel sheets that have been processed through a cold reduction process, which enhances their strength, surface finish, and dimensional accuracy. This manufacturing technique involves passing hot-rolled steel through a series of rollers at room temperature to reduce thickness and improve surface quality.

Advantages of CR Sheets

1. Precise Dimensional Tolerance:

CR Sheets are known for their outstanding dimensional accuracy, making them ideal for applications that demand tight tolerances. Manufacturers can rely on CR Sheets to ensure precise product specifications.

2. Improved Surface Finish:

The cold rolling process results in a smoother and more uniform surface finish compared to hot-rolled steel. This enhanced finish is beneficial for applications where aesthetics and appearance matter.

3. Increased Strength:

CR Sheets exhibit higher tensile and yield strength compared to hot-rolled counterparts. This makes them suitable for applications that require robust and durable materials.

4. Reduced Thickness Variability:

CR Sheets have minimal thickness variations across the sheet, ensuring uniformity and consistency in the final product. This is crucial for manufacturing processes that demand even thickness throughout.

Mild Steel (MS): A Versatile Choice

Mild Steel (MS) is a type of carbon steel with low carbon content, making it exceptionally malleable and easy to work with. MS is renowned for its versatility, making it a preferred material across various industries.

Advantages of Mild Steel (MS)

1. Excellent Formability:

MS’s low carbon content allows it to be easily formed, welded, and machined into various shapes and sizes. This makes it an ideal choice for manufacturers seeking flexibility in design and production.

2. Cost-Efficiency:

Mild Steel is cost-effective compared to many other materials. Its availability and affordability make it a popular choice for budget-conscious manufacturers without compromising on quality.

3. Durability:

MS offers excellent durability and resistance to wear and tear, making it suitable for applications exposed to harsh environmental conditions.

4. Wide Range of Applications:

Mild Steel’s versatility allows it to be used in a wide range of applications, from construction and automotive to industrial machinery and consumer products.

Conclusion

In conclusion, the advantages of CR Sheets and Mild Steel (MS) in modern manufacturing are clear and compelling. Their unique properties, including dimensional accuracy, strength, formability, and cost-effectiveness, make them indispensable choices for a wide range of industries and applications. By leveraging the strengths of these materials, manufacturers can achieve superior product quality, cost savings, and increased competitiveness in today’s dynamic market. Whether used individually or in tandem, CR Sheets and Mild Steel continue to play pivotal roles in shaping the modern manufacturing landscape.