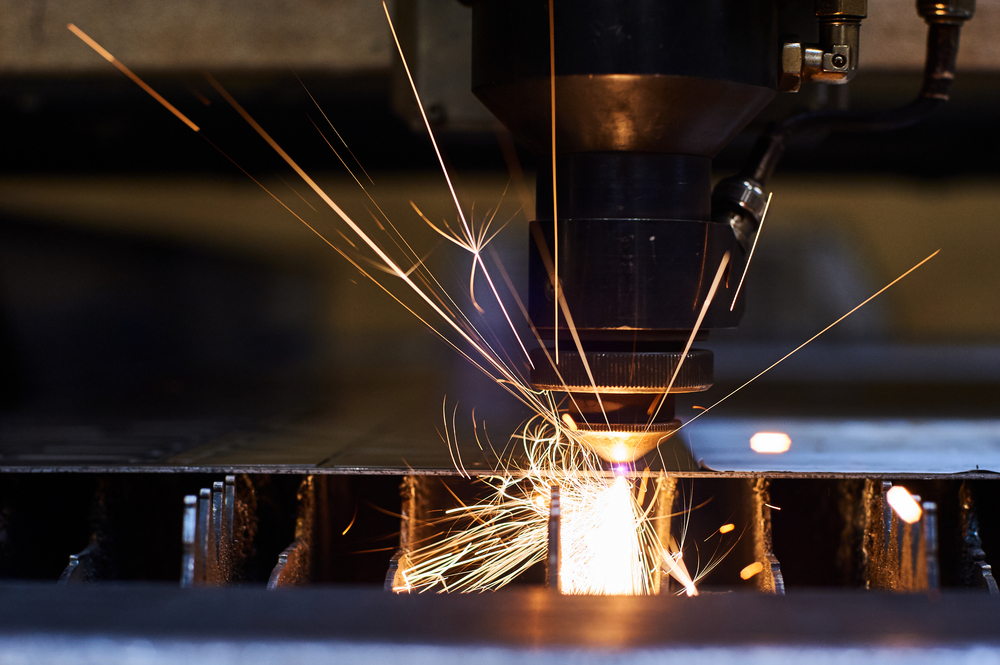

Laser-cutting systems have emerged as the epitome of precision and efficiency in modern manufacturing. This cutting-edge technology has revolutionised the way industries shape and mould materials, offering unparalleled accuracy and versatility. Let’s delve into the intricacies of laser cutting systems and explore how they are reshaping the landscape of fabrication.

Precision Redefined: The Core of Laser Cutting Systems

At the heart of laser cutting systems lies the ability to achieve microscopic precision. Utilising focused laser beams, these systems can cut through a myriad of materials, from metals to polymers, with razor-sharp accuracy. This precision is a game-changer, especially in industries where intricate detailing is non-negotiable.

Versatility Across Materials: Beyond Boundaries

One of the standout features of laser cutting systems is their ability to traverse the diverse landscape of materials. Whether you’re working with stainless steel, acrylic, wood, or intricate composites, these systems adapt seamlessly. This versatility makes laser cutting an ideal choice for industries with varied material demands.

Speed and Efficiency: Meeting Demands in Real-Time

In the fast-paced world of manufacturing, time is of the essence. Laser-cutting systems operate at remarkable speeds, ensuring efficient production processes. The swift and precise nature of laser cutting not only enhances productivity but also allows for the rapid prototyping of designs.

Intricate Designs, Unmatched Quality: The Artistry of Laser Cutting

Beyond mere functionality, laser cutting systems enable the creation of intricate and complex designs. Whether it’s delicate patterns, intricate engravings, or precisely cut components, the artistic possibilities are limitless. This capability opens doors for industries where aesthetics and functionality intertwine.

Cost-Efficiency and Waste Reduction: A Sustainable Approach

Laser cutting minimises material waste through its pinpoint accuracy. The ability to nest components efficiently in raw materials reduces the overall waste generated during the manufacturing process. This not only contributes to cost savings but also aligns with the growing emphasis on sustainable and eco-friendly practices.

Automation Integration: Streamlining Production

The integration of laser cutting systems with automation technologies further enhances their efficiency. Automated loading and unloading of materials, coupled with computer numerical control (CNC) capabilities, ensure a seamless and streamlined production process. This integration is a testament to the ongoing Industry 4.0 revolution.

Quality Assurance: Meeting and Exceeding Standards

Precision, versatility, and efficiency converge to uphold stringent quality standards. Laser cutting systems consistently deliver outputs that meet and often exceed industry benchmarks. This commitment to quality assurance positions these systems as indispensable tools for industries that prioritise excellence.

Future Trends: Beyond the Horizon

As technology advances, so do laser-cutting systems. The future promises even greater precision, faster speeds, and expanded material capabilities. As industries evolve, laser cutting stands ready to adapt, providing a glimpse into a future where the boundaries of fabrication are continually pushed.

In conclusion, laser cutting systems represent a paradigm shift in the world of manufacturing. Their precision, versatility, and efficiency redefine what’s possible in fabrication, offering industries a tool that not only meets but exceeds expectations. As we continue to witness technological advancements, laser cutting remains at the forefront, shaping the future of how we create and build.